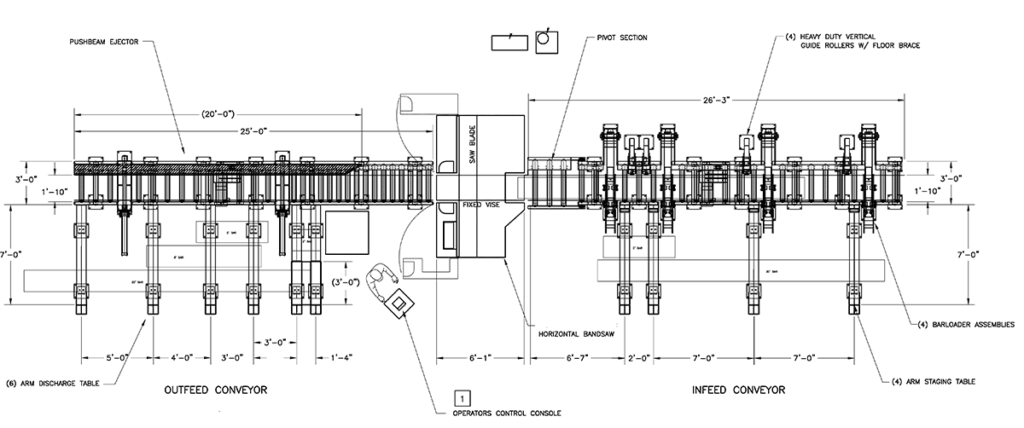

Modular Components and Engineered Systems To Meet Your Specific Requirement

Steel Storage Systems designs and manufactures heavy-duty conveyor components and custom integrated systems to meet your specific material handling requirement. Systems include Powered and Gravity Conveyors, Transfer and Cross Conveyors, and Load and Discharge Systems.

Get a Quote!

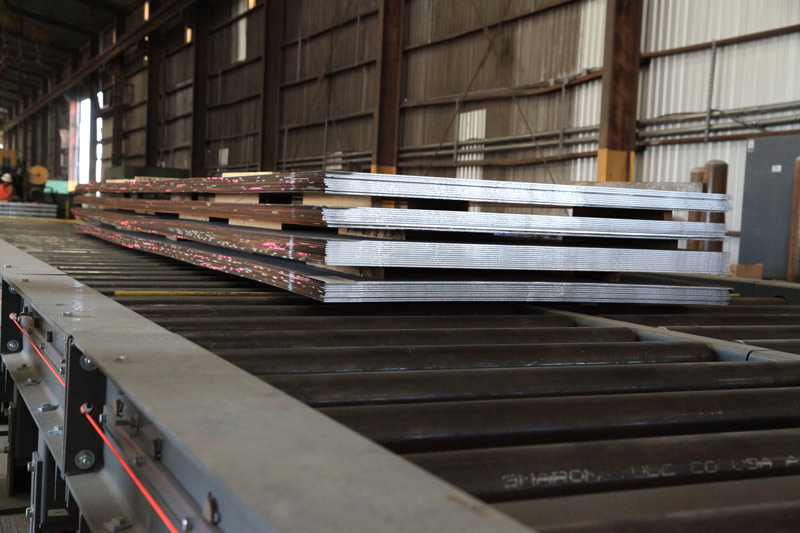

Powered and Idler Roller Conveyors

We offer both Chain-Driven Powered Roller Conveyors, CDLR Conveyors, and Idler Roller Conveyors. A standard heavy-duty line, as well as special-designed extreme-duty sections, are available. We tailor roller widths, spacing, and capacities along with conveyor lengths for every customer and application. Powered Conveyors are furnished with controls, and we offer a broad list of conveyor accessories and parts to enhance safety and productivity.

Chain Transfer and Cross Conveyors

Chain Transfer Conveyors and Cross Conveyors provide lateral powered staging, discharge, and accumulation of material for Roller Conveyors. They provide a continuous flow of material to and from processing equipment for uninterrupted operation resulting in maximum productivity. Chain Transfer Conveyors and Cross Conveyors are alternative designs each with inherent advantages depending on the application.

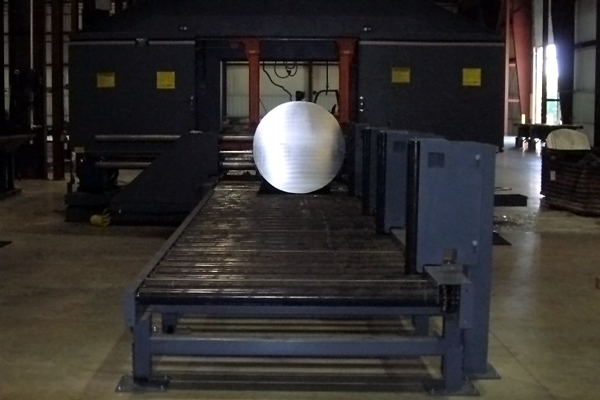

Bar and Pipe Loading and Discharge Conveyors

Load and Discharge Systems are an economic alternative to Transfer and Cross Conveyors for staging and feeding round material onto a roller conveyor and discharging. The Bar and Pipe Loader is designed to utilize the gravity flow properties of rounds. The Push-Bar Ejector disposes of cut lengths of material onto discharge skids. These systems provide a continuous flow of round bar, pipe, and tubing to and from processing equipment for uninterrupted operation resulting in maximum productivity. These custom material handling solutions are alternative designs each with inherent advantages depending on the application.

Powered and Manual Measuring Systems

We offer the Heavy-Duty Powered Workstop and a Light-Duty Manual Workstop to maximize saw processing efficiency. The Powered Measuring Workstop features controls for positioning, clamping, and a readout at the operator’s console. The Manual Workstop slides along a track mounted to the Roller Conveyor and is aligned with a tape measure.