Modular Components and Engineered Systems To Meet Your Specific Requirement

Round Bar, Pipe & Tube Loaders

Loaders are a less expensive alternative to Transfer and Cross Conveyors for staging and feeding round material onto a Roller Conveyor. The Bar and Pipe Loading System comprises a staging magazine and lifting pawl and uses the gravity flow properties of round bar, tube, and pipe. The magazine is a series of inclined skids on which material is staged and fed to the pawl. The pawl picks the material and elevates it to a ramp that rolls onto the Roller Conveyor.

Bar and Pipe Loading Systems are an economical alternative to Transfer and Cross Conveyors for staging and feeding round material onto a Roller Conveyor using gravity flow properties.

The magazine skids are tailored in length and quantity per requirement, and the lifting pawl can be supplied to handle practically any range of sizes and weights. Thus, Loader Systems can accommodate a combination of remnants and stock lengths. The pawl is hydraulically powered to raise and lower, and index to the width of the load. The standard indexing range is 0 to 16” wide with adjustability to lift a single diameter or several pieces at a time.

Loader Systems include controls and a hydraulic power unit.

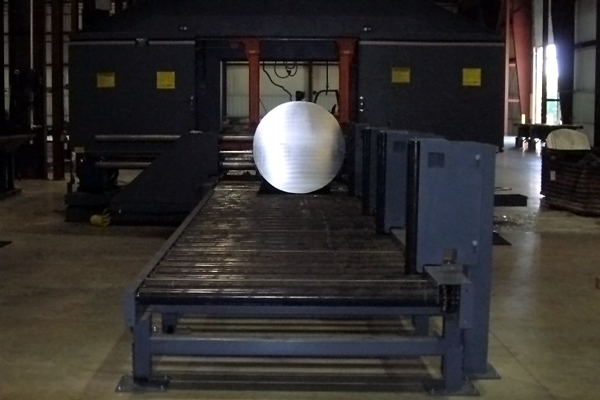

The Pushbar Ejector

The Pushbar Ejector is an electric device employed on outfeed Roller Conveyors to remove material, typically cut pieces. The Pushbar mounts just above the rollers and sweeps across the conveyor “pushing” material onto discharge skids. It can be furnished in lengths up to 40’ and a 10,000lb capacity.

Its design allows for disposing of a wide range of lengths from shorts to the full outfeed. The system clears material from the outfeed conveyor table with a quick, safe motion to increase cutting productivity.

Steel Storage Systems designs, manufactures, and installs custom material handling solutions for numerous applications. We work with you to meet your metals storage and handling goals with attention to quality, safety, and service. Contact us to learn more about our material handling solutions!