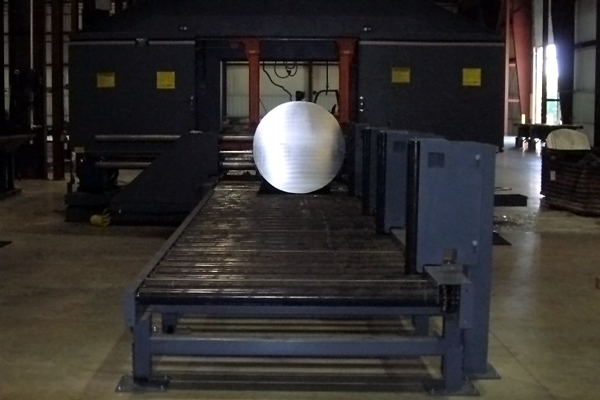

Modular Components and Engineered Conveyor Systems to Meet Your Specific Requirements

Roller Conveyors are heavily constructed to stand up to the wear and abuse of handling steel and to last for many years of operation. They are furnished in 10’ or less modular sections that bolt together to form any length required. The modular design allows for easy shipping, assembly, and rearranging.

Steel Storage Systems Roller Conveyors integrate with metal saw systems, cut-to-length (CTL) lines for steel sheet, shot blasters, tube mill exit lines, order-filling, and packaging lines. Roller conveyor tables facilitate bay to bay and inside to outside movement of material in metal service centers, tube mills, and fabricators.

Roller Conveyor Sizes

Steel Storage Systems offers Roller Conveyor Tables with custom roller sizes, frames, and legs for extreme heavy-duty material handling equipment. Standard conveyor tables are available in 22”, 32”, and 42” roller widths and in a variety of spacings to meet any application. Roller sizes, frames, and legs can be specified for extreme heavy-duty applications. All conveyor sections are manufactured to your height specification, and the legs are equipped with +/- 1 1/2” adjustment.

Idler Roller Conveyor Tables

Idler Roller Conveyors are offered in all the same sizes and options as powered sections. These Roller Conveyor Sections can be used for many applications within various industries with a heavy focus on material handling equipment and transition

Roller Conveyor Accessories & Parts options are available:

- Drip Pans with a PVC pipe recovery system

- Removable Filler Plates

- Vertical Guide Rollers for material alignment

- Lift Rollers

- Pivot Sections and Safety Gates to create walkways

Powered Roller Conveyors

Powered Roller Conveyors are typically supplied with variable speed electric drives operated with a joystick control. The CDLR conveyor drive chain is wrapped roller-to-roller and covered by removable formed chain guards. In addition to custom roller sizes, Powered Conveyor drives and chains can be specified to fit the application. Steel Storage System’s customization options include clutched drives, safety guards, and Measuring Systems to provide safe and efficient material handling.

Large Conveyors are 96″ or wider and 80′-200′ long to support shot blasting equipment with options such as tilting plates at 45-degree angles. Check out our Custom Material Handling Systems to learn more about unique roller conveyor applications!

Roller Conveyor Sections for Accessibility and Altering Flow

A Moveable Idler Roller Conveyor Section rolls in and out of the way on a track to accommodate a pivoting miter saw while maintaining the ability to convey short pieces.

A Turntable Powered Roller Conveyor Section accomplishes a 90-degree material flow change.

A Live Roller Conveyor Pivot Section creates a temporary aisle by hydraulically raising 90 degrees.

All CDLR Conveyors are supplied with controls including a pre-wired voltage panel and operator’s console. Controls are designed to the desired operation and plant voltage.

Transfer Conveyors and Load and Discharge Systems further increase material handling productivity and efficiency when integrated with Roller Conveyors by providing accumulation and discharge. Load Rails, Push Bar Ejectors, and Vertical Guide Rollers also support the material staging and discharge process.

Contact Steel Storage Systems to learn more about Powered and Idler Roller Conveyor Applications!