Modular Components and Engineered Systems To Meet Your Specific Requirement

The Powered Workstop

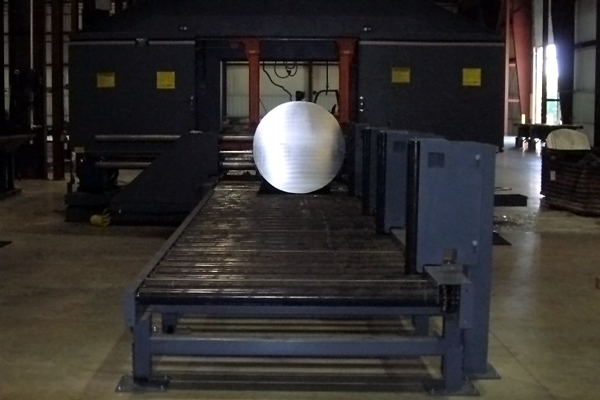

The Powered Workstop stages and measures material for saw processing in fabrication facilities and metal service centers, increasing convenience, precision, and efficiency. The Workstop mounts to a track attached to the Steel Storage Systems’ saw outfeed Roller Conveyor Table and can accommodate any length. In addition, the Measuring System’s rugged construction will endure decades-long harsh industrial working conditions.

The Advanced Measuring System includes a closed-circuit camera that displays a tape measure readout on an LCD monitor located on the system control console. This system is operated from a console with controls for positioning, clamping, lowering, and raising functions. Slow-down and stop sensors minimize the impact of material on the arm, and a contact light illuminates to notify the operator when the material is in position. In addition, the Powered Workstop enables the operator to measure, stage and cut material without stepping away from the console. Reach out to Steel Storage Systems today for more information on our Conveyor and Material Handling Equipment.

The Manual Workstop

The Manual Workstop is a simple device for light-duty applications, recommended only with idler roller conveyors and the cutting of smaller bars, shapes, and tubes. Like the Powered Workstop, it mounts to a track attached to the outfeed roller conveyor, but it is manually aligned to a tape measure on the track, clamped with a locking lever, lowered, and raised.

Advanced Measuring Systems are designed exclusively for Steel Storage Systems’ Conveyors

Contact Steel Storage Systems to get started on your Conveyor Project!