Modular Components and Engineered Systems To Meet Your Specific Requirements

Round Bar, Pipe & Tube Loaders

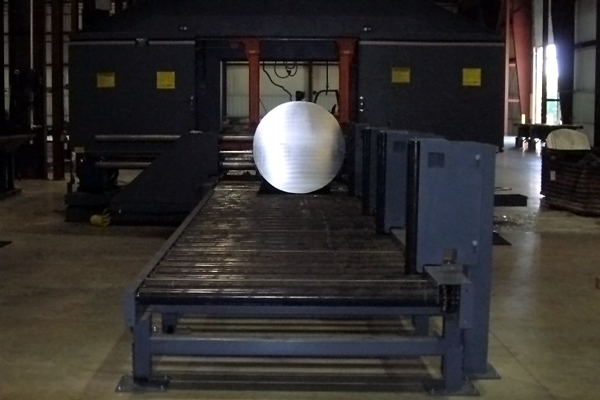

Load systems are an economical alternative to Transfer and Cross Conveyors for staging and feeding round material onto a Roller Conveyor. These material loading systems take advantage of the natural gravity flow properties of round bar, pipe, and tube to stage and deliver material efficiently.

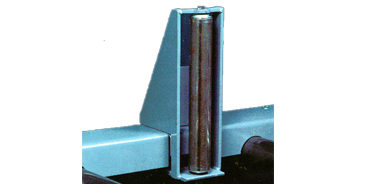

Each bar or pipe loader features a staging magazine — composed of inclined skids — and a hydraulically powered lifting pawl. Once material is loaded onto the skids, the pawl raises and advances it to a ramp. The pawl acts as a lifting transfer conveyor, elevating round material smoothly onto the conveyor line.

Magazine length and skid quantity are configured to match your layout and material types. The bar loader’s lifting pawl can be engineered for a wide range of diameters, lengths, and weights — including both remnant and full stock lengths. Standard indexing ranges from 0 to 16″, with flexibility to lift single or multiple pieces at a time.

All Loader Systems are supplied with a hydraulic power unit and integrated controls.

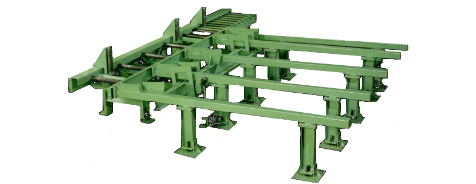

The Pushbar Ejector

The Pushbar Ejector is a device that can be mounted on outfeed Roller Conveyors to remove material, typically cut pieces. The Pushbar mounts just above the rollers and sweeps across the conveyor, “pushing” material onto discharge skids.

Pushbar Ejectors can be manufactured in lengths up to 40’ and 10,000lb in capacity. Its design allows for moving a wide range of lengths from shorts to full outfeed length. The ejector enhances productivity by clearing material quickly and safely between cycles and streamlines conveyor discharge operations for automated material handling.

Why Choose Steel Storage Systems?

- Over 60 years of experience designing, manufacturing, and installing custom material handling solutions.

- Proven powered and gravity-fed load systems designed to streamline staging and transfer.

- Custom-engineered solutions, such as bar and tube loaders, built to match your material sizes and workflows.

- American-made equipment built for long-term reliability and production demands.

- Responsive, knowledgeable support from system design through final installation.

Get a Quote for Custom Load & Discharge Solutions

Steel Storage Systems provides engineered solutions that integrate with your layout, material types, and production workflow. Whether you’re handling bar, pipe, or tube, our team will configure a load system, pipe loader, or pushbar ejector tailored to your operation.

Contact us today to request a quote and learn how our automated material handling systems can improve throughput, safety, and efficiency across your material loading systems.

Explore More Solutions

- Transfer & Cross Conveyors – Improve lateral material movement between conveyor lines and machines.

- Powered Roller Conveyors – Discover joystick-controlled sections for smooth, continuous flow.

- Parts Tumbler – Automate the finishing process for cleaner, consistent results.

Conveyor Case Studies