Modular Components and Engineered Systems To Meet Your Specific Requirement

Chain-Driven Transfer Conveyors

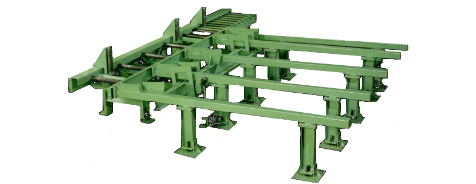

Transfer and Cross Conveyors are designed to accumulate, feed, and move materials efficiently throughout warehouse operations. These lateral Transfer Conveyor systems feature multiple arms connected by heavy-duty, motorized chains that link to a shared drive shaft, enabling lateral material transport, maintaining steady, sequential material flow throughout.

The arms of the transfer and cross conveyors can be configured in various quantities and spacing arrangements to accommodate nearly any length requirements. We offer custom transfer tables that are available in multiple sizes and lengths, with arm capacities reaching up to 25,000 pounds.

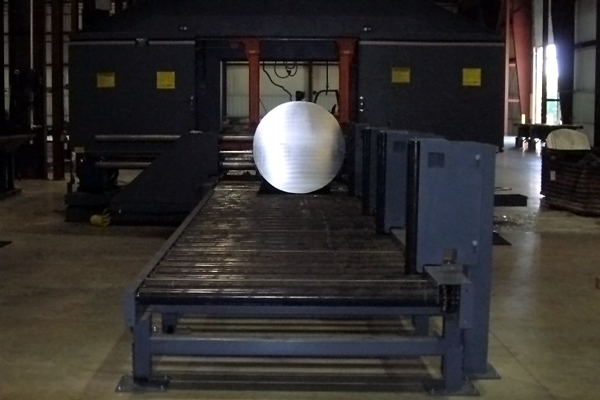

Transfer conveyors are often integrated with roller conveyor tables to facilitate staging and discharge operations for processing equipment such as bundlers and saws. The arms cross through the roller conveyor system and are equipped with hydraulic lifting cylinders that raise and lower to control and facilitate material loading. Transfer Conveyor Systems enable uninterrupted material flow for high-volume production, optimizing overall productivity.

Chain-Driven Cross Conveyors

Cross Conveyors perform the same core function as Transfer Conveyors by moving material laterally but offer the added benefit of unlimited accumulation capacity. This makes them especially well-suited for multi-process handling systems like fabrication beam lines or conveyor-to-conveyor transfer.

These systems use a lift-and-carry mechanism that raises material above the arms before transporting it laterally. Arm quantity and length can be configured to support a wide range of material sizes and facility layouts.

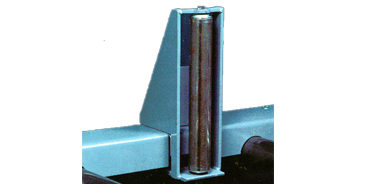

Cross Conveyors are typically supplied with joystick-controlled, variable-speed electric drives. Each unit features roller-to-roller chain-driven conveyor systems protected by removable chain guards. Drives, roller sizes, and chains can all be specified for your application, with clutched drive options available for additional safety and control.

Each arm includes a fixed load rail or transfer skid to support resting material. When inactive, the lift transports stow and reposition beneath the load rail. The fixed rails allow these systems to support tremendous weight without being limited by length. This lift-and-carry design enables convenient and independent operation — ideal when multiple operators share a transfer process between machines.

Load and Discharge Systems for Round Stock

Steel Storage Systems also offers Load and Discharge Systems — conveyor solutions for staging and feeding bar, pipe, and tube. Designed specifically for round stock, these systems work similarly to Transfer and Cross Conveyor Systems but use gravity flow to stage and deliver material onto Roller Conveyor lines with speed and efficiency.

Why Choose Steel Storage Systems?

- Over 60 years of experience engineering material transfer systems for metal processing and manufacturing.

- Custom-engineered conveyor systems and storage racks built for heavy, continuous-duty operation.

- Lift-and-carry and crane-accessible designs that improve flow and safety.

- Flexible configurations that integrate with roller conveyors, beam lines, and staging.

- Consultation, installation, and product support: Steel Storage Systems provides expert consultation from concept to construction.

Get a Quote

Steel Storage Systems provides consultation, installation, and replacement parts for all of our material transfer systems, conveyor systems, and racking solutions.

Contact us today to get help selecting or customizing the right equipment for your operation.

Explore More Solutions

- Beam Rotator – Improve bundle orientation and simplify handling for structural steel components

- Load & Discharge Systems – Stage and feed round material efficiently with these economic systems

- Sheet Racks – Organize flat product storage near lasers, shears, and press brakes

Conveyor Case Studies