Learn what parts tumblers are, how rotary tumblers remove burrs and slag from steel parts, and why automated finishing outperforms manual methods.

In This Guide:

What is a Parts Tumbler, and Why Are They Used?

A parts tumbler is a piece of machinery that relies on a tumbling, rotary motion to remove burrs, slag, scale, or rust from machined parts. These machines have become essential in modern metals centers, metal fabrication shops, and parts manufacturing facilities for the ease in which they transform rough, cut components into clean, finished parts ready for welding, coating, or assembly.

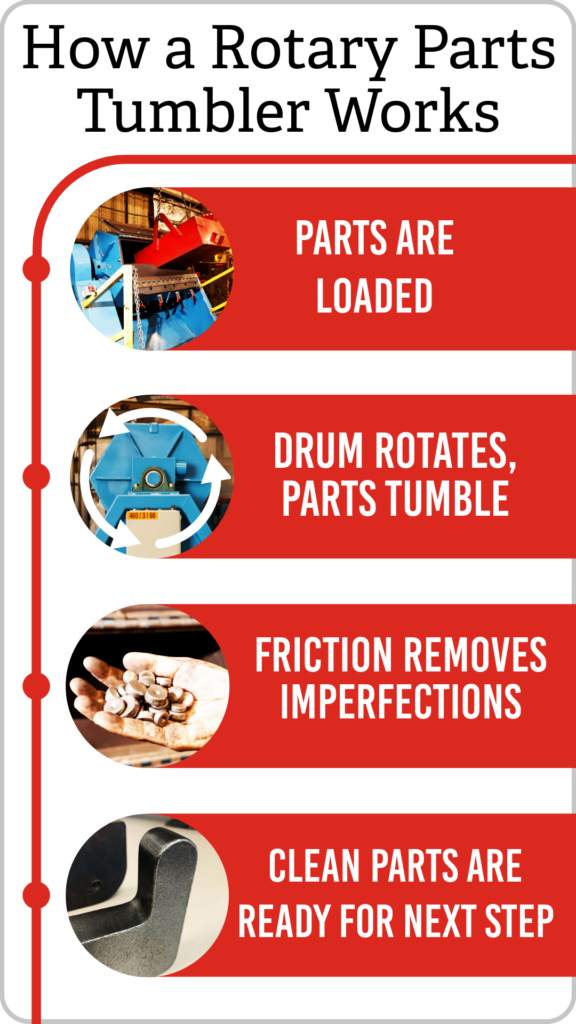

Parts tumblers work by agitating components with or without abrasive media, creating friction that gradually removes surface imperfections, slag from heat-cutting, mill scale, rust and sharp edges and burrs. The process is automated, cost-effective, and capable of finishing large batches of parts without requiring constant operator supervision.

Why Are Industrial Parts Tumblers Used by Fabricators and Service Centers?

The primary function of a parts tumbler is to remove imperfections created during cutting and fabrication processes. Thermal cutting leaves slag deposits and heat-affected zones with scale and oxidation along cut edges. Machining operations that include milling, drilling, sawing, and punching create burrs where material is sheared or cut, forming sharp metal protrusions along edges and holes. Mill scale, which forms naturally during steel manufacturing when hot steel reacts with oxygen, adheres to structural steel, plate, and bar stock. Rust and corrosion develop when steel is exposed to moisture during storage or transport, creating surface oxidation that must be addressed before further processing.

These imperfections create significant downstream problems. Slag, scale, and rust contaminate weld zones, causing porosity, weak joints, and structural defects. Coating adhesion fails when paint, powder coating, or galvanizing is applied over contaminated surfaces, leading to premature failure and corrosion. Sharp burrs pose safety hazards to workers and can cause improper fit during assembly. Manual deburring and cleaning can address these issues, but the labor-intensive process creates production bottlenecks—which is where automated tumbling transforms the finishing process.

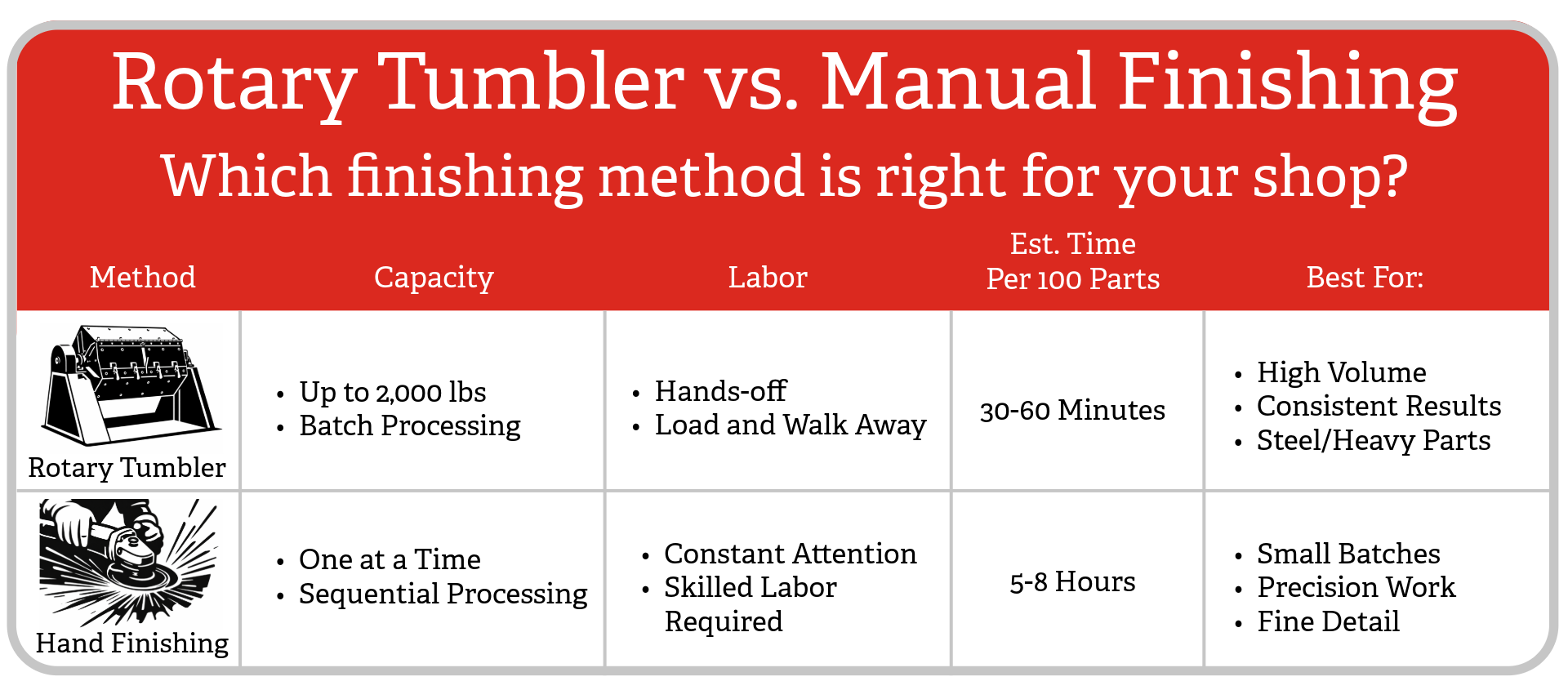

Rotary Tumblers Versus Manual Finishing: Understanding the Difference

When selecting a finishing method, fabricators face a fundamental choice: automated finishing such as rotary tumblers or manual finishing with planers, deburring tools, and grinders. While both methods remove slag, scale, rust, and burrs, they differ significantly in mechanism, efficiency, and ideal applications.

How Processes Differ: Form and Function

Rotary tumblers use a rotating barrel that lifts and drops parts in a continuous tumbling motion. This allows parts to abrade against tumbling media, other parts, and the barrel walls simultaneously. The process is straightforward and powerful, driven by gravity and momentum, making it ideally suited for high-volume finishing of durable metals like steel.

Why Rotary Parts Tumblers Are the Right Choice for Metals Processing

Rotary tumblers are the superior choice for heavy-duty industrial metal finishing applications. Steel fabrication shops, steel processors, and machine shops working primarily with steel and heavy materials benefit most from rotary technology:

Processing Capacity

Handle up to 2,000 lbs. per cycle, allowing shops to process entire production runs in a single tumbling cycle rather than deburring parts individually.

Durability for Tough Materials

The barrel design and gravity-driven tumbling action provide aggressive cleaning power suited to steel, which requires more force than softer metals to remove slag and scale effectively.

Minimal Supervision Requirements

Unlike manual finishing, rotary tumblers run complete cycles automatically, freeing operators for welding, fitting, or other value-added tasks.

Cost Efficiency at Scale

The combination of high capacity, automated operation, and minimal maintenance makes tumblers an ideal solution in form, function, and cost.

Key Features of the Parts Tumbler from Steel Storage Systems

Dependability and Heavy-Duty Construction

From a reliability standpoint, the Rotary Parts Tumbler from Steel Storage Systems offers significant advantages in demanding industrial environments. Our engineers have thoughtfully designed our tumblers to work well with minimal maintenance or operator oversight. Engineered with minimal components, to include the base, tumbler body, motor, rubber liner, and vacuum dust collector, you can be assured minimal labor time for upkeep and years of continuous operation. Many of our tumblers remain in service for decades with only periodic replacement of the rubber liners, which decrease noise and barrel wear. From a reliability standpoint, the Rotary Parts Tumbler from Steel Storage Systems offers significant advantages in demanding industrial environments. Our engineers have thoughtfully designed our tumblers to work well with minimal maintenance or operator oversight. Engineered with minimal components, to include the base, tumbler body, motor, rubber liner, and vacuum dust collector, you can be assured minimal labor time for upkeep and years of continuous operation. Many of our tumblers remain in service for decades with only periodic replacement of the rubber liners, which decrease noise and barrel wear.

Steel Storage Systems manufactures our rotary parts tumblers with heavy-duty bearings, simple chain drives, and thick-walled barrels specifically for heavy industrial use—they can be run nearly nonstop, leading to less frequent repairs, less downtime, longer service life, and lower overall cost of ownership.

High Capacity for Production Environments

Process up to 2,000 lbs. of material per cycle with no specific size limit for parts as long as they can revolve loosely in the chamber. This flexibility accommodates everything from small brackets and flanges to structural components, providing versatility for shops that handle diverse part geometries.

Hands-Off Operation with Minimal Supervision

Operators simply load the parts and start the machine. The tumbler runs automatically through the complete cycle, freeing valuable labor hours for other productive tasks such as operating material handling equipment or managing conveyor systems.

Integrated Dust Collection

Integrated vacuum dust collectors continuously extract dust and fine particles from the tumbling chamber during operation. This produces cleaner finished parts by removing debris during processing, eliminates airborne particulate that could resettle on components, and creates a safer work environment by preventing respiratory irritants from entering the shop atmosphere.

Parts Tumbler Applications

Steel Fabrication and Flame Cutting Operations

Industrial parts tumblers excel at cleaning heat-cut steel components. Oxyfuel cutting processes leave slag deposits and heat-affected zones that must be removed before welding or coating. The tumbling action effectively breaks away slag and removes the scale and oxidation that forms during thermal cutting processes, ensuring clean parts that weld better and achieve stronger coating adhesion.

Fabrication shops that produce brackets, gussets, mounting plates, structural components, and other flame-cut parts rely on tumblers to prepare these parts for further processing. Clean parts weld better and achieve a stronger coating adhesion.

Deburring and Finishing Machined Parts

Machining operations create burrs and sharp edges that pose safety hazards and can interfere with assembly. Parts tumblers remove these burrs automatically, creating smooth edges that are safe to handle and assemble. This process is particularly effective for parts with multiple holes, edges, or complex geometries where manual deburring would be time-consuming and inconsistent.

Removal of Rust and Scale

Rust and scale prevent effective welding and interfere with coating adhesion. Tumblers thoroughly clear rust and scale from cut parts, providing an economical alternative to sandblasting or chemical cleaning. This is especially valuable for shops working with structural steel, plate steel, and other products that typically arrive with mill scale or develop rust during outdoor storage.

a Marked Reduction in Scale and Rust

Why Steel Fabricators Choose Rotary Parts Tumblers from Steel Storage Systems

For shops producing structural steel, industrial equipment components, machinery parts, or products requiring clean metal surfaces, a rotary parts tumbler from Steel Storage Systems represents foundational equipment that improves quality, increases productivity, and reduces operating costs through automated finishing.

With over 60 years of experience manufacturing material handling and processing equipment, Steel Storage Systems understands the challenges faced by modern metals centers and fabricators. Our rotary parts tumbler is engineered for reliability in demanding production environments, delivering consistent performance for steel fabrication shops, structural steel processors, and machine shops throughout North America.

Ready to maximize throughput, improve safety, and reduce production times? Contact us now for a quote.

Frequently Asked Questions About Parts Tumblers

Do parts tumblers require constant operator supervision?

No, parts tumbler machines are designed for automated operation without constant supervision. Operators simply load the parts into the chamber and start the machine. The tumbler runs automatically through the complete cycle, freeing valuable labor hours for other productive tasks. This hands-free operation is one of the key advantages that makes parts tumblers so cost-effective for busy fabrication shops.

How much maintenance do rotary parts tumblers require?

Rotary parts tumblers from Steel Storage Systems are engineered for minimal maintenance. With only a few key components, there are fewer parts that can fail or require service. Many tumblers remain in service for decades with only periodic replacement of the rubber liners. Routine maintenance includes inspection of drive chains and bearings, along with cleaning the dust collection filters. This simplicity translates to less downtime and lower overall cost of ownership.

Do I need special media or compounds for tumbling?

Rotary parts tumblers can operate effectively with just the parts themselves, using part-on-part abrasion to remove burrs and clean surfaces. However, some applications benefit from adding abrasive tumbling media to enhance the cleaning action. The choice depends on your specific materials and desired finish.

How does integrated dust collection work?

The integrated vacuum dust collector continuously extracts dust and fine particles from the tumbling chamber during the cleaning cycle. As parts tumble and friction removes imperfections, the dust collection system vacuums away the resulting debris. This produces cleaner finished parts, prevents dust from settling back onto components, and creates a safer work environment by keeping metal dust and particulate out of the shop atmosphere.

Transform Your Metal Finishing Operations

Rotary parts tumbling eliminates the bottleneck of manual cleaning and deburring, allowing your operation to process more work with consistent quality. A rotary parts tumbler from Steel Storage Systems can lower your overall operating cost through reduced labor costs, improved part quality, faster throughput, system longevity, and enhanced workplace safety.

Whether you’re establishing a new fabrication facility or upgrading existing finishing capabilities, understanding how parts tumblers work and their applications help you make informed equipment decisions. Our rotary metal parts tumbler combines heavy-duty construction, high capacity, and integrated dust collection to meet the demanding requirements of industrial metal processors.

With over 60 years of experience in manufacturing material handling and processing equipment, Steel Storage Systems understands the challenges faced by modern metals centers and fabricators. Our industrial parts tumbler machine is engineered for reliability in production environments, delivering the consistent performance your operation requires.

Steel Storage Systems serves steel centers throughout North America with storage solutions including SpaceSaver roll-out cantilever racks for long material, sheet metal storage racks for plate and sheet inventory, and custom conveyor systems that optimize material flow through your facility.

Ready to improve your parts finishing process?

Contact Steel Storage Systems today at (800) 442-0291 to learn more about our industrial rotary metal parts tumbler and discuss how it can improve efficiency and product quality. Visit our parts tumbler product page or speak with our experienced team about your specific requirements.